5 Which Element Includes the Use of Root Cause Analysis

The use of Root Cause Analysis. Systemic Actions look comprehensively across all involved systems to prevent future events and promote sustained improvement.

7 Powerful Problem Solving Root Cause Analysis Tools

The most commonly used comprehensive systematic analysis is the Root Cause Analysis RCA.

. Start studying Quiz 3. Identifies one root cause for each priority performance concern the. Failure-based RCA is used in engineering and maintenance to determine the root cause of any type of equipment failure.

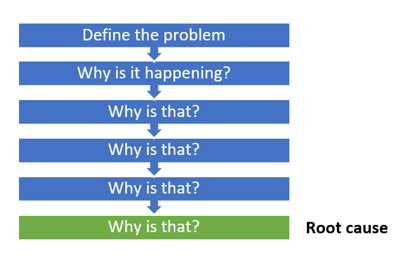

An RCA is a specific type of focused review that is used for all patient safety adverse events or close calls requiring analysis. The 5 Whys and 5 Hows have also been described as being like a ladder. The 5 Whys refer tothe practice ofasking five timeswhy the situation has occurred in orderto get to theroot causes of the problem.

A 5 Whys analysis sometime could be taken further to a sixth seventh or higher level but five iterations of asking why are generally sufficient to get to a root cause. Failure mode and effects analysis. Root cause analysis RCA is a way of identifying the underlying source of a process or product failure so that the right solution can be identified.

Systemic Actions look comprehensively across all involved systems to prevent future events and promote sustained improvement. RCA assumes that it is much more effective to systematically prevent and solve for underlying issues rather than just. Here are each of the criticisms as listed on the Wikipedia.

This element includes a focus on continual learning and continuous improvement. A set of 5 why questions lead the team to dig deeper into the problem speed up the problem-solving process and enable them to. Remember that the PMBOK definition of risk includes opportunities as well as threats.

In this context root cause analysis is used not only to identify where corrective action needs to be taken but also opportunities for process improvement. In both quantitative and qualitative. You move down the ladder using the 5 Whys to drive down to the root cause and then climb up the ladder using the 5 Hows to get to a resolution to the problem.

The goal of root cause analysis is to find out. A root cause is defined as a factor that caused a nonconformance and should be permanently eliminated through process improvement. The 5 Whys is a technique used in the Analyze phase of the Six Sigma DMAIC Define Measure Analyze Improve Control methodology.

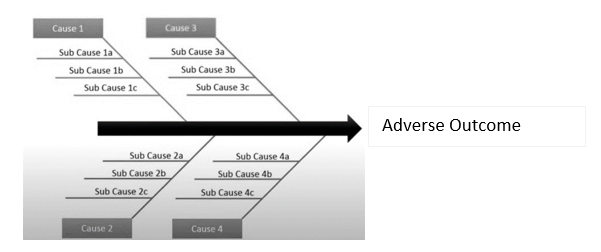

Root cause analysis RCA is defined as a collective. Root cause analysis RCA is the process of discovering the root causes of problems in order to identify appropriate solutions. Materials defective raw material Man Power lack of knowledge or skill MachineEquipment defective equipment or tools Environment orderly workplace physical demands of the task Management poor management involvement stress demands.

Fifth why a root cause Note. The RCA is a process for identifying the basic causal factors underlying system failures and is a widely understood methodology used in many industries. Systems-based RCA originated as a combination of some of the root cause analysis techniques listed above.

The team will review Why did the. Root cause analysis can be used to uncover factors that lead to patient. RCA can progress more quickly and effectively by pairing an Ishikawa diagram with the scientific method in the form of the well-known plan-do-check-act PDCA cycle to empirically investigate the failure.

Stopping at symptoms not the root cause. The 5 Hows are then used to determine a root or permanent solution to the root cause s of the problem. Plan Element definition Criteria Root Causes Statements describing the deepest underlying cause or causes of performance challenges that if dissolved would result in elimination or substantial reduction of the performance challenges.

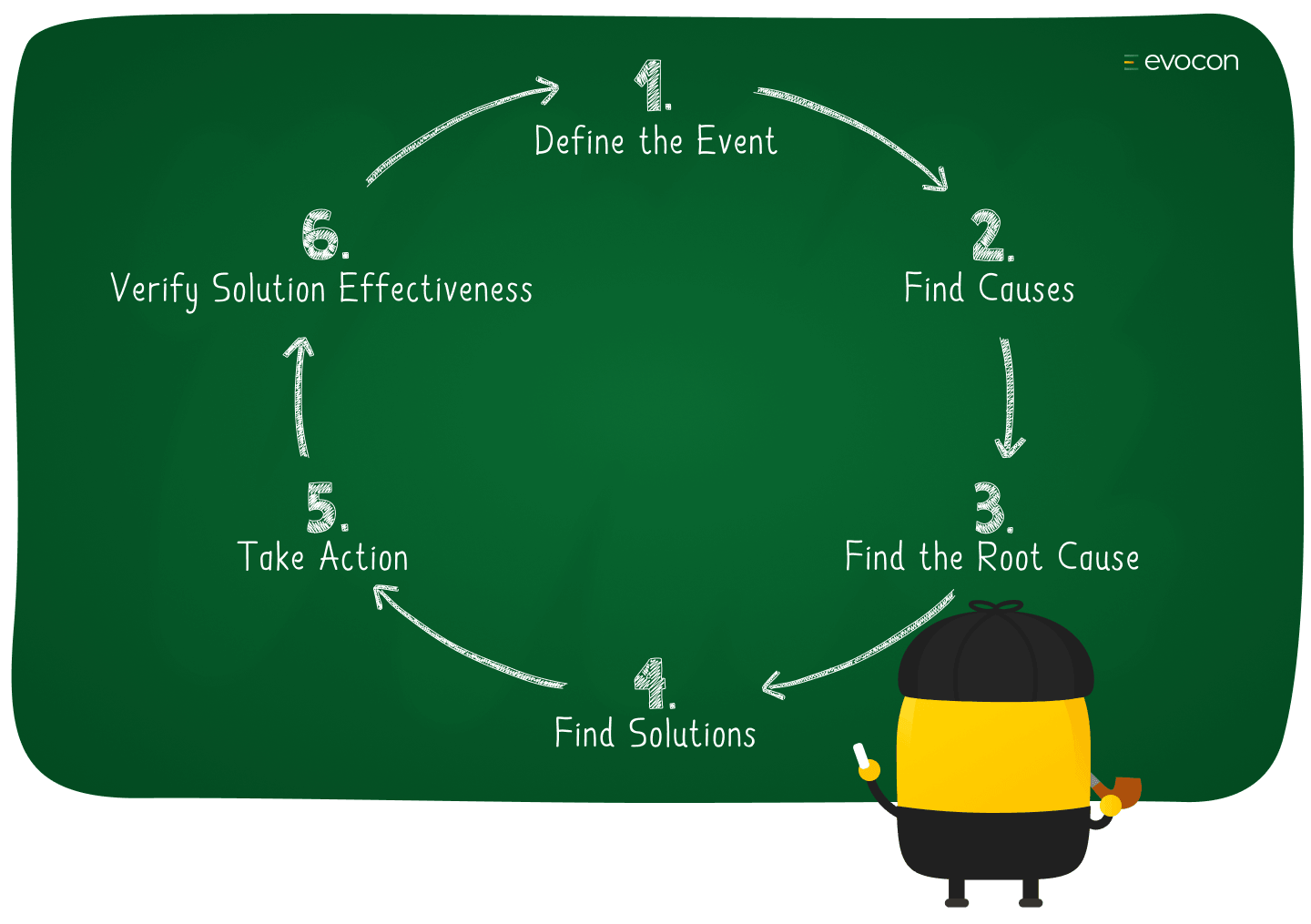

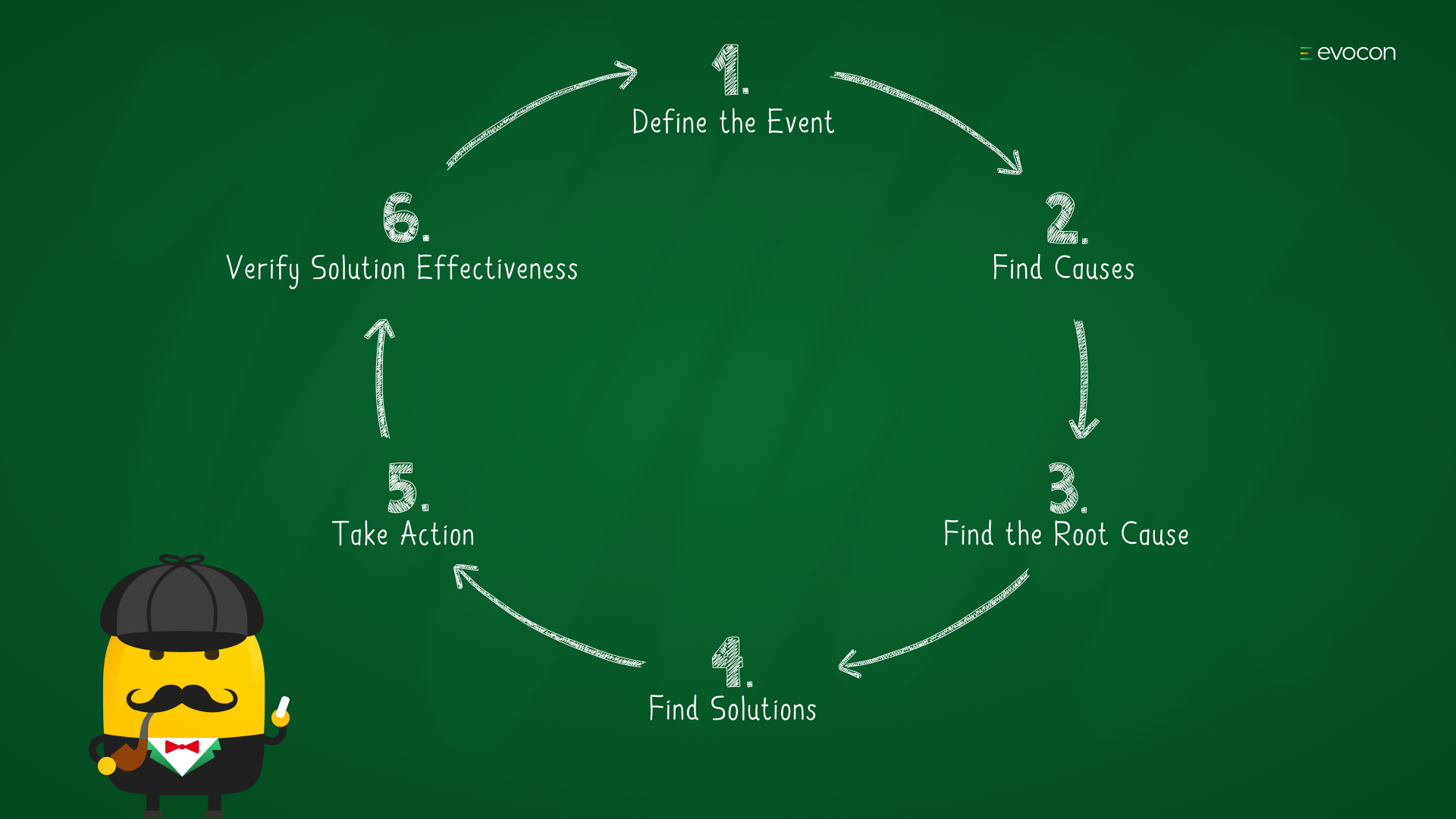

Root Cause Analysis RCA Step-By-Step Guide RCA is a process for identifying the basic or contributing causal factors that underlie variations in performance associated with adverse events or close calls. Feedback data systems and monitoring. The use of Root Cause Analysis.

Project risk management root cause analysis is a specific technique used to identify project risks. Element 5 Systematic Analysis and Systemic Action Understand and focus on organizational processes and systems Model and promote systems thinking Flowcharting Practice RCA get to the root of problems. Which element of QAPI includes identifying reporting analyzing and preventing adverse events and near misses.

The 5 whys fishbone analysis helps determine the causes of the problem and finds out the root causes. By repeatedly asking the question. Basic elements of a root cause are divided into different categories with examples of each in parentheses.

It is a great Six Sigma tool that does not involve data segmentation hypothesis testing regression or other advanced statistical tools and in many cases can be completed without a data collection plan. This element includes a focus on continual learning and continuous improvement. The root cause is the core issuethe highest-level causethat sets in motion the entire cause-and-effect reaction that ultimately leads to the problem s.

This methodology is an approach that combines two or more methods of RCA. It illustrates the importanceof digging down beneaththe most obvious causeof the problemFailure to determine the root cause assures. Why an event occurred.

Learn vocabulary terms and more with flashcards games and other study tools.

How To Conduct An Effective Root Cause Analysis 5ms E

Fishbone Diagram Root Cause Analysis Pros Cons

Root Cause Analysis By Operational Excellence Consulting Operational Excellence Analysis Problem Solving

Root Cause Analysis Tracing A Problem To Its Origins By Tahmina Naznin Cybridge Geeks Medium

The Astounding Root Cause Analysis Template Root Cause Analysis Templates In Root Cause Analysis Template Business Template Professional Templates Powerpoint

Fishbone Diagram Root Cause Analysis Pros Cons

![]()

Root Cause Analysis Ishikawa Diagrams And The 5 Whys

Fishbone Diagram Root Cause Analysis Pros Cons

Root Cause Analysis Forms Analysis Situation Analysis Corporate Image

7 Powerful Problem Solving Root Cause Analysis Tools

Root Cause Analysis Forms Check More At Https Nationalgriefawarenessday Com 49750 Root Cause Analysis Forms Analysis Good Essay Sample Resume

5 Step Root Cause Analysis Diagram For Powerpoint Slidemodel

5 Step Root Cause Analysis Diagram For Powerpoint Slidemodel

Root Cause Analysis Tracing A Problem To Its Origins By Tahmina Naznin Cybridge Geeks Medium

Root Cause Analysis Ishikawa Diagrams And The 5 Whys

Lean Manufacturing Sixsigma Zero Defects 無欠陥 Part 1 Of 3 Change Management Lean Six Sigma Lean Sigma

How To Perform Root Cause Analysis In 6 Steps Evocon

Comments

Post a Comment